Scary! Less than a month until the “real” deadline of the Pintobotics project, EOH 2024. We’ve come a long way in 9 months and now is the time to deviate a little from reaching blindly for the dream and focus on making something we can be proud of in April.

The Dream:

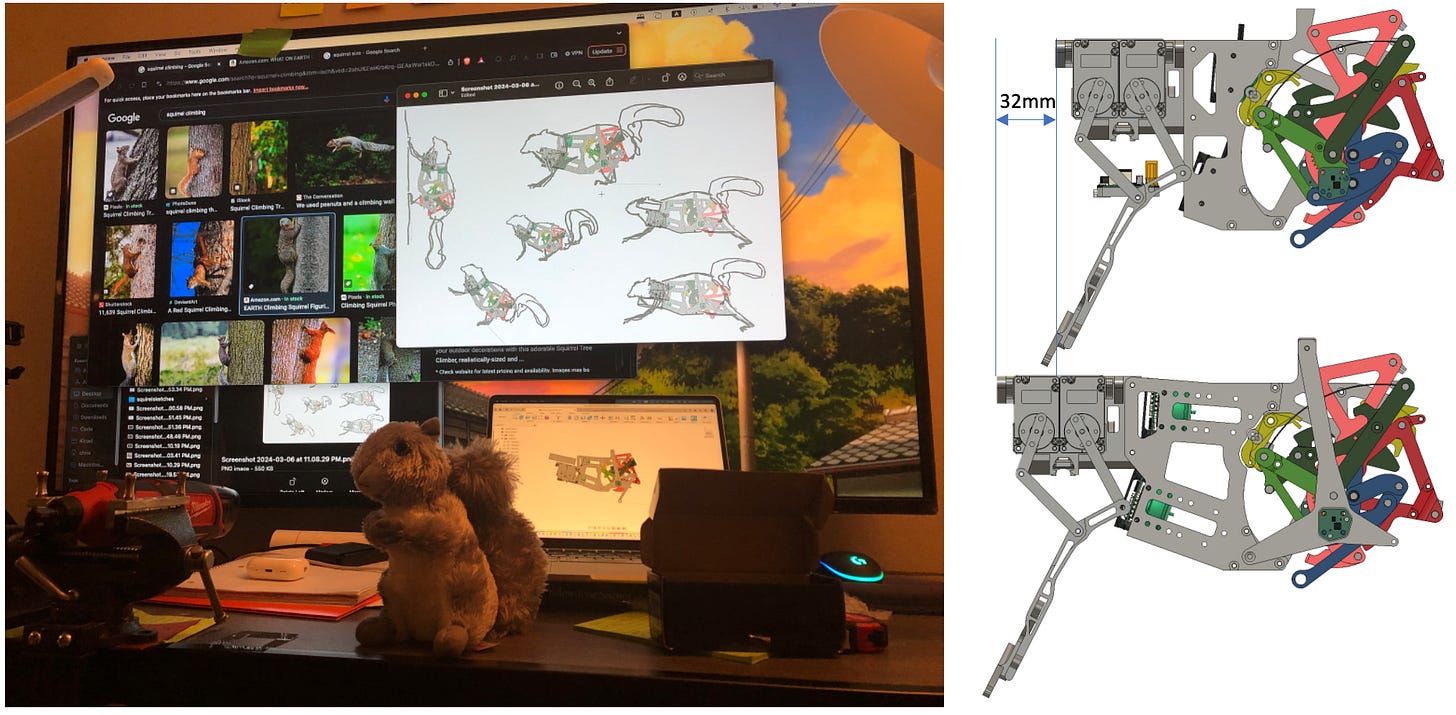

The very-long-term ideal for Pinto would be a robot whose actions make it nearly indistinguishable from a squirrel (hence the “squirrel turing test”1). We hope to accomplish that by designing specialized mechanisms, combined with creating intuitive teleoperation with human-machine interfaces scaled down to squirrel size.

I have a feeling that high-bandwidth teleoperation will be the easiest way to demonstrate the full potential of the type of agile robot we are aiming for. If a human is able to effectively control each joint with intention, given enough practice we can probably solve hard trajectory generation problems like jumping between small footholds and onto surfaces with arbitrary orientations. I’m avoiding complex control algorithms because robots like these don’t exist yet, so my goal is to demonstrate the potential and worry about repeatability later.

25 days

This dream is so alluring that it’s sometimes hard to get out of optimizing for the future, like making the design look more squirrel-shaped and trying to find the length of string that works best for winding up the back leg springs. There is limited time and we are already saturated on effort, so some things will need to be saved for next month.

I realized this when I found myself trying to get the back leg to jump more and more. Tuning the mechanism for jumping by itself is informative, but not the highest priority for demo because we haven’t really tested the front legs at all. We should be focusing first on making sure all the parts are there for running, jumping, and landing, even if it’s not as far of a jump as expected.

Originally I wanted to design a custom joystick controller for EOH, an improvement on the 8-axis joystick from before to achieve independent control of each joint. However I decided to go with a regular gamepad to save time thinking about how to make controlling so many joints more intuitive and not have to debug custom electronics. On the other hand, we will have to spend more time creating high-level commands in software to use sequences for moving forward, turning, windup/jump, and flipping over.

Speaking of custom electronics…

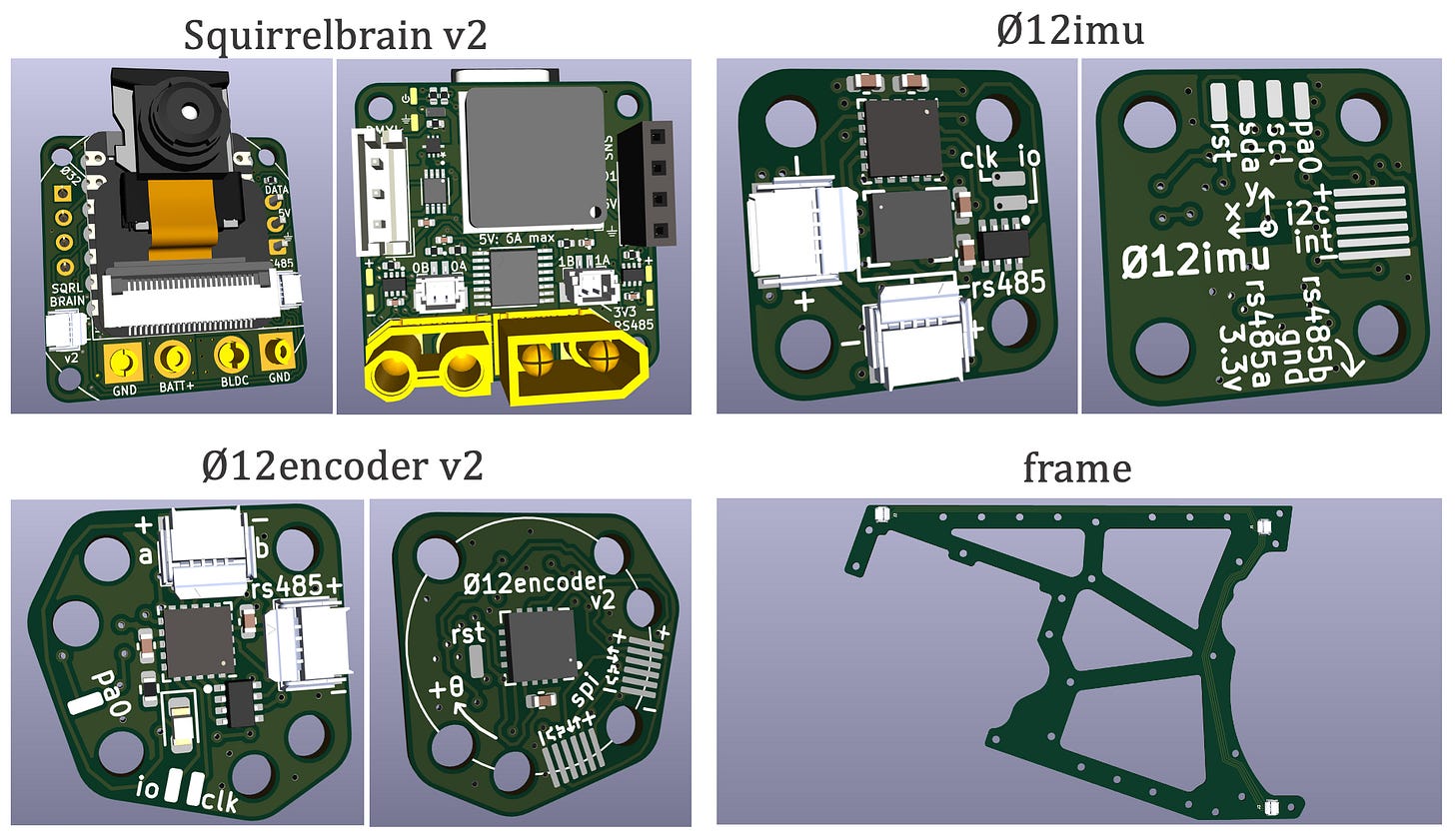

There are 4 more things to debug! These PCBs should be arriving next week:

Ø12imu: a new board with an IMU and built-in sensor fusion for the RS485 bus. Orientation from the gyro and accelerometer is computed by the chip itself (LSM6DSV), which reportedly has less drift than using a conventional integrator/filter and saves computation time. We’ll use orientation data to help with turning on the ground, aiming for jumps, and datalogging.

Ø12encoder v2: added FFC connectors and fixed an SPI wiring issue (forgot to connect CS directly)

Squirrelbrain v2: added FFC connectors for the RS485 buses so it’s easier to connect encoders and IMU

Frame: just a weirdly shaped PCB that happens to fit on the side of the squirrel body. Using 0.8mm FR4 is about 50% the weight of our currently 3D printed PLA frame and likely similar in strength on the same plane. It might need to be reinforced more in the other directions because it is so thin, but worth a try. Just for fun, I added FFC connectors so we can mount an encoder on one end of the frame, squirrelbrain on the other, and have the signals pass through the frame to make the wiring neater.

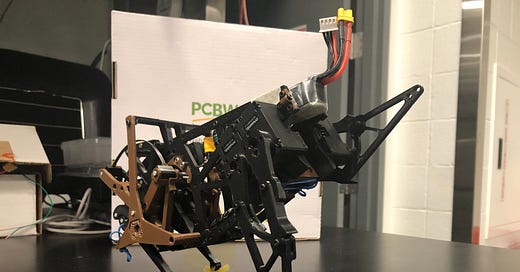

Front arms

We redesigned the front arms to support the squirrel better for jumping tests, with endstops so the 5-bar never reaches singular configurations. It has a larger range of motion that allows it to wave, but we’ll probably need to make the arms even longer. Instead of pushing up quickly then jumping while the front is off the ground, it would be more reliable to aim to the tree by extending the arms down all the way to the ground.

Windup tester

We built the windup testing stand described last time to be able to quickly test different springs and configurations. Out of 4 different strings (100lbs braided “Kevlar” kite string, 50lbs braided PE fishing line, 100lbs braided PE fishing line, and unrated unbraided PE bowstring), the black and white unbraided PE bowstring we have been using for the fast few months seems to be the best for our twisting application. For each string, I tested 1, 2 and 4 strands to find a thickness winds up all 8 carbon fiber springs (4 strands for kite string, 2 strands for 50lbs fishing line, 2 strands for 100lbs fishing line, 4 strands for bowstring). Adding more strands make it stronger but reduce the force produced. All tests were performed with the pulley 64mm away from the motor, with strings around 77mm.

The kite string snapped after just a few cycles (which makes me wonder if it’s actually Kevlar?) and had a lot of wear, while the braided fishing line tended to fold back on itself at certain times which made it have different discontinuous stages of winding where the diameter of the twisted string would suddenly increase. It seems that it often gets stuck trying to complete a fold so the internal string forces suddenly increase and the string snaps. The unbraided string seemed to increase in radius more smoothly, so didn’t have this issue.

Mechanical fixes

I found out that the carbon fiber springs could be protected against snapping dramatically by wrapping tape around its midpoint, which makes them delaminate peacefully instead.

There has been many minor adjustments on the back leg linkage to fix clearance issues, reduce friction, and reinforce certain parts so all the springs can be added. There were some joints with shaft rotating inside 3D printed holes, which we replaced with Igus bushings. The outer links holding the springs tended to twist from the high spring force.

There are some more fixes like making sure the springs don’t touch the ground when winding up for a jump and adjusting the line of action to be more vertical, which we should get done in the next week. We also have to make sure the claws from the previous robot still work with this one.

Also, turns out we can just buy a tree climbing squirrel on Amazon for $27 :)

Many more things to happen, will keep you updated!

-Chris

Credit to Juan David for coming up with the phrase “squirrel turing test“

25 days to go!! You guys got this!!!

Nice CF hack with the tape in the middle. Delamination better than the piece snapping. Curious, does it create stress points anywhere else on the body? Any cracks? How useful is the piece to you after it has been delaminated?

Also, please tell me that you got the Climbing Squirrel Figurine!!

EOH GET READY!!!!!