Sorry for the lack of posts lately! The past month and a half we’ve been intensely redesigning for robot reliability and preparing for demos. Almost every part of the robot, including the software, has changed at least slightly.

EOH

We’ve been building up for Engineering Open House (EOH) all year, and expectations were high. There were some challenges the first day, and though the robot didn’t perform as well as we’d liked, it was a great success!

About a week before the event, we recorded this video of a mini tree-jump:

After one of our meetings, we thought it would be fun to line up the robot to the tree, why not. It worked the first time! We weren’t even recording. It took us maybe 10 more tries before we got it on camera.

That was probably the most exciting part of the project so far. It felt like a huge accomplishment to us because the latched jump got high enough to be completely on the tree and the grippers worked perfectly; we could really see the tree-jumping dream coming true.

However, this wasn’t enough for a 2-day long demo to the general public. It wasn’t reliable, and it’s not the most exciting to watch us spend a minute setting up the robot for jump that lasts only a second. One of the issues was that the jump wasn’t actually that powerful, so the landing angle had to be near perfect to force the front arms apart to grip the tree.

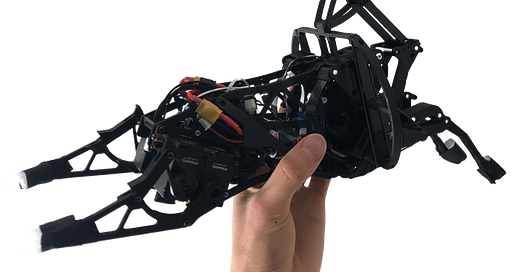

I loaded more springs and replaced the brushless motor with a more powerful one. Also, I added a bistable mechanism to improve the reliability of resetting the latch. The latch used to be held in place by friction and could be moved to any continuous position, resulting in the leg mechanism sometimes not fully latching and releasing spring energy before intended. By adding an elastic, the latch has only two stable positions, either fully latched or fully unlatched.

However, adding more power backfired. It worked a few times at home, but there wasn’t enough time to fully test. On the cold morning the first day of EOH, the string kept on snapping due to the more powerful motor and springs. Later that day, we pivoted to showing the prototypes on the table and testing videos. A bit disappointing because of most people come to EOH on the first day, but they still seemed to enjoy learning about our project.

Before the second day, we replaced the string and epoxied the loose joints. Software limits (30% motor power, better position tracking) were put into place to avoid overloading the string. We also decided to focus solely on jumping horizontally across the ground. This way, we could let the audience control the robot themselves, and there were no issues operating the robot nonstop all day.

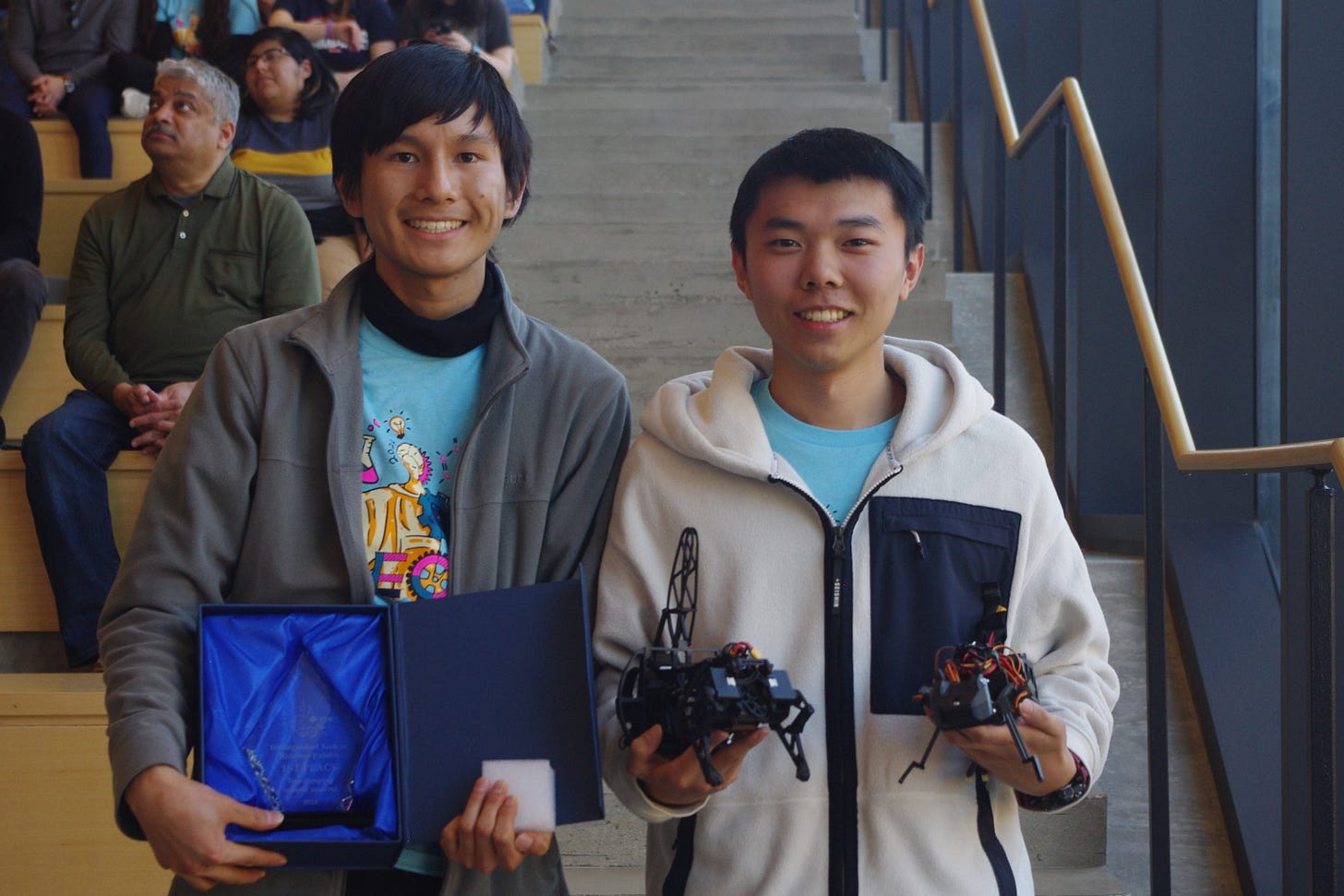

It was much more engaging and it made us happy to see many kids eager to play with Pinto. Even with fewer people the second day, our exhibit continued to gather a small crowd. At the end of the event, we were awarded with 1st place Distinguished Tech/Robotics Exhibit!

Here’s us talking with Aaryaman from the UIUC Talkshow:

Robot Block Party

A week later was the Robot Block Party at the Museum of Science and Industry in Chicago. Basically, EOH part 3.

This video showcases the tail, one of the additions to the robot since the last newsletter. It adds the characteristic look of a squirrel, and also helps with standing back up if the robot falls over.

At this event we also got to meet other robotics researchers at Northwestern and UChicago, and it was really cool hearing about their projects. In particular, check out Northwestern’s one motor drone!

Research Presentations

Next, we presented at the UIUC MechSE Research Showcase and then the Undergraduate Research Symposium. We demoed the robot in both cases, so it felt like EOH parts 4 and 5. These were shorter events, and we got more experience talking about the research side of our project: developing mechanisms to perform a tree jump. We also got to show one of the experiments, which looks at the rear foot forces during a series-elastic jump:

An initial observation is that the forces actually go negative before the jump, showing that the rear foot may lose contact briefly when the front arms are pushing up. Also, Fy (vertical force) drops faster than Fx (horizontal force), showing that near the end of the jump, the net force is mostly horizontal and the foot would likely slip if not pinned in place.

The next demo/presentation will be on May 13, at the impulsive motion workshop at ICRA 2024 in Yokohama, Japan. We are very fortunate to show our project to an international robotics community!

We have 6 more experiments planned for the summer, so hopefully we figure how to improve the jump further.

1,2,3: Compare jump forces and velocity with latched parallel-elastic, series-elastic, and no spring

4: Latched jumping at different angles by adjusting spring release timing

5: Pose tracking with unlatched back leg

6: Jump and catch onto the tree 10 times, record success rate

7: Record max speed of walking and turning on flat ground

We’re aiming to write about this process in a paper submission to ICRA this September!

By “showing off”, sharing our project goals and getting the robot to a presentable state, we made decisions about what parts of this project are most important to us and it excites us to see others excited about the same things. It’s so rewarding when someone comes up after a demo and says, “I want to build my own robot now, thank you!”

That inspiration keeps all of us jumping.